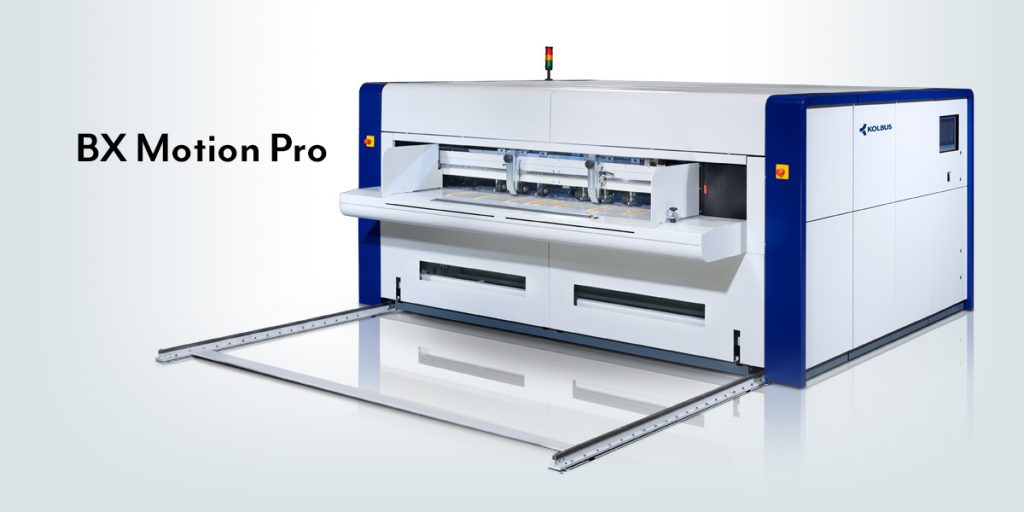

The BX Motion Pro is the radical new shortrun boxmaking system that brings previously undreamt of levels of flexibility and adaptability to your process. Re-designed from the ground up, you will benefit from groundbreaking new build quality and reliabilty.

The modular design empowers you to make customised single, double and triple wall boxes with selectable tool configurations, adaptable to your specific production needs. You can even add extra functionality to give inline digital print and inline gluing – all in a single pass

Transport rollers and tools are positioned automatically according to FEFCO code and format, with automated adjustment of all creasing/cutting tools on the horizontal axis for precise positioning

With flexibility at its very core, modules can be individually adapted to meet all you requirements and the way you work, even including the sequence of individual processes. With the BX Motion Pro, you do things your way!

- From E-flute all the way up to a maximum of 15mm

- Set-up in less than 60 seconds

- Make around 100 FEFCO box styles

- Digital print anywhere across the width and length of a box in one or several locations

- Automatic feeding and stacking

- Inline glue strip application

Specify your bespoke boxmaking solution from the following optional functionality

Infeed/ Feed section

The Bx Motion Pro comes as standard with a built in, table feeder with high traction belts to pull in the bottom sheet from a stack from board supported using a simple trolley. Automatic feeding is an option with the AUTO-FEED AF300.

Creasing Tools

Options for a range of creasing profiles to convert whatever grade you require

- Material thickness is set up automatically

- Top crease, bottom crease roller

- Single and double crease

- Male/female creasing tools

- 1-point, 2-point and 3-point creasing depending on board weight

- Servo-controlled drive of both creasing tools

HD Line Cutting

- Up to 15 mm thickness

- HD Shear Cut Ø 180 mm

- Servo-controlled drive

- Side trim can be shredded and transported out of the machine

- Material thickness up to 15 mm

Inline Digital Printing

- Up to 8 twin 140mm print units

- Resolution 360 dpi single colour – additional colours are possible

- Cleaning station for print heads outside of the module

Cross cutting

- Pneumatically controlled

Inline Gluing

- Cold glue, automatic nozzle gluer for selected areas

Glue flap Crush

- Pneumatically controlled flap crush with adjustable pressure and transport slide

- Width up to 40 mm

Die Cutting

Automatic set up of diecut stations

Slotting

- Manual loading of the knife holders

- Automated cross creasing and correction of creasing depth

- Cross conveyor belt for waste

Multi-Out option

- Produce up to 3 out across width in one pass

- Auto setting of outer slotting knives

- Manual set for inner knives

Delivery

- Delivery table, collects blanks for stacking

- AutoStacker option automatically collects and stacks blanks on scissor lift table

Sales manager

Zandis Zvirbulis

SIA Kolbus

27769059

zandis@kolbus.lv

Click here, to view the Broschure

Click here, to view the Box Styles pdf file.