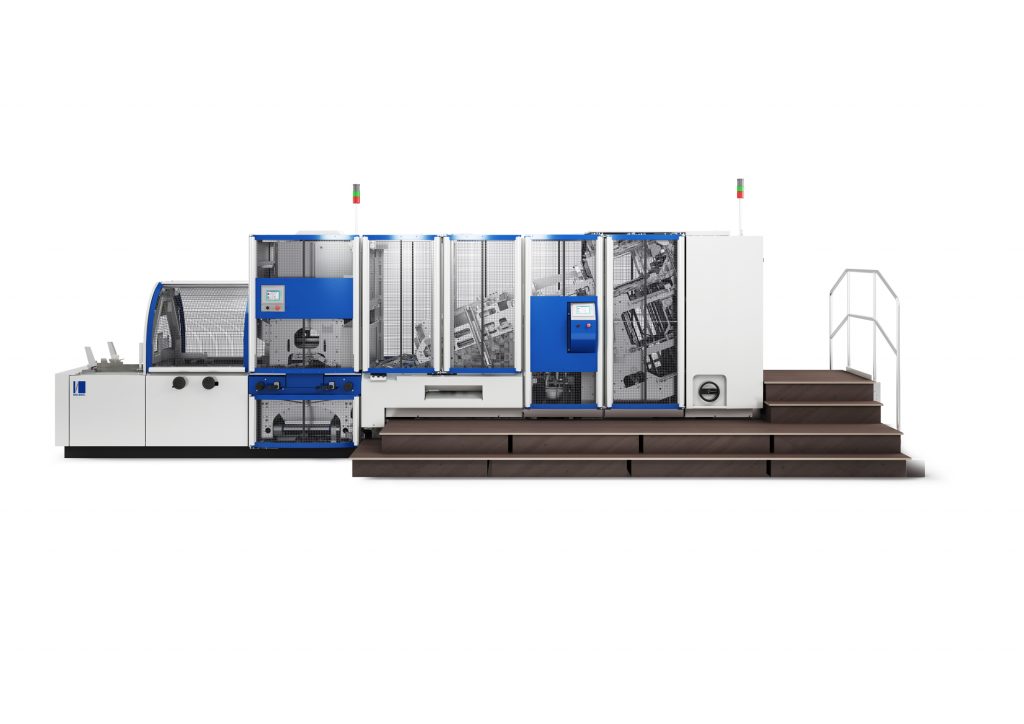

Box-Machine-Line SW.E_SW.H

Corner puncher SW.E 500 – for punching cross grooved boards

Box machine SW.H 500 – for production of boxes from cross grooved and corner punched boards

Benefits

A new way of making boxes

- Boxes with wrap-around lids, slip-on lids or shoulder boxes with precision angles, sharp edges and corners

- Short set-up times

- Format changes without retooling

- Precisely cold-glued by the grooves

Features

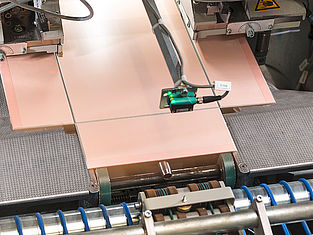

- Precisely separation and alignment of the precut boards

- Corner puncher with four corner knives

- Boxes from cross-grooved precut boards

- Cold gluing unit for gluing the grooves

- Erecting unit for side walls

Size range (width x height x thickness)

board min.: 140 x 140 x 1.5 mm | max.: 735 x 5257 x 4 mm

Box height (external dimensions): min.: 20 mm | max.: 170 mm

Box bottom ( external dimensions): min.: 65 x 65 mm | max.: 570 x 360 mm

Size range punched corner: dependent to the external dimensions

Mech. speed

up to 40 cycles/min

for box height > 115 mm – max.: 35 cycles/min

for box height > 135 mm – max.: 30 cycles/min

for box height > 150 mm – max.: 25 cycles/min

Net production is subject to sizes, materials etc.

Pārdošanas vadītājs

Zandis Zvirbulis

SIA Kolbus

Tel. 27769059

zandis@kolbus.lv